Pipe Relining: A Revolutionary Alternative to Traditional Pipe Repair and Replacement

The integrity of your property's plumbing system is paramount to its functionality and the well-being of its occupants. Over time, pipes are susceptible to damage caused by factors such as age, wear and tear, and tree root intrusion; addressing these issues with urgency is imperative to avoid long-term structural or sanitary problems. In the past, repairing or replacing damaged pipes often involved invasive procedures that were time-consuming, costly and disruptive to both the property and its occupants.

However, recent advancements in plumbing technology have brought forth revolutionary methods that are changing how pipe maintenance and repair is conducted. Pipe relining, a groundbreaking solution that provides a minimally invasive yet highly effective alternative to traditional pipe repair, is quickly becoming the preferred approach for addressing various piping issues.

In this comprehensive article, we will explore the ins and outs of pipe relining; its methodology, benefits, and how it compares to conventional pipe repair methods. Gain insight into the expertise offered by DCG Plumbing and how their seasoned team utilises modern technology to deliver exceptional pipe relining services that guarantee durability, efficiency, and minimal disruption to your property.

1. The Pipe Relining Process: A Comprehensive Overview

Pipe relining, a trenchless repair technique, involves the use of a resin-impregnated liner to create a new pipe within the damaged one, restoring its function and integrity without excavation.

Step-by-Step Procedure

1. Inspection: The pipe relining process begins with a thorough assessment of the damaged pipe, typically employing CCTV drain inspection technology to determine the extent of the problem and locate the precise area of concern.

2. Cleaning: The next step involves cleaning and preparing the damaged pipe, which often involves using high-pressure water jetting to remove any debris or blockages.

3. Measuring and Cutting: The pipe is accurately measured, and a custom-made liner is cut to the required length, ensuring a seamless fit.

4. Resin Impregnation: The liner is saturated with a specially-formulated resin, which will harden upon curing and form a watertight, durable new pipe within the existing damaged pipe.

5. Liner Insertion: Using specialised equipment, the resin-impregnated liner is inserted into the damaged pipe and positioned accurately over the affected area.

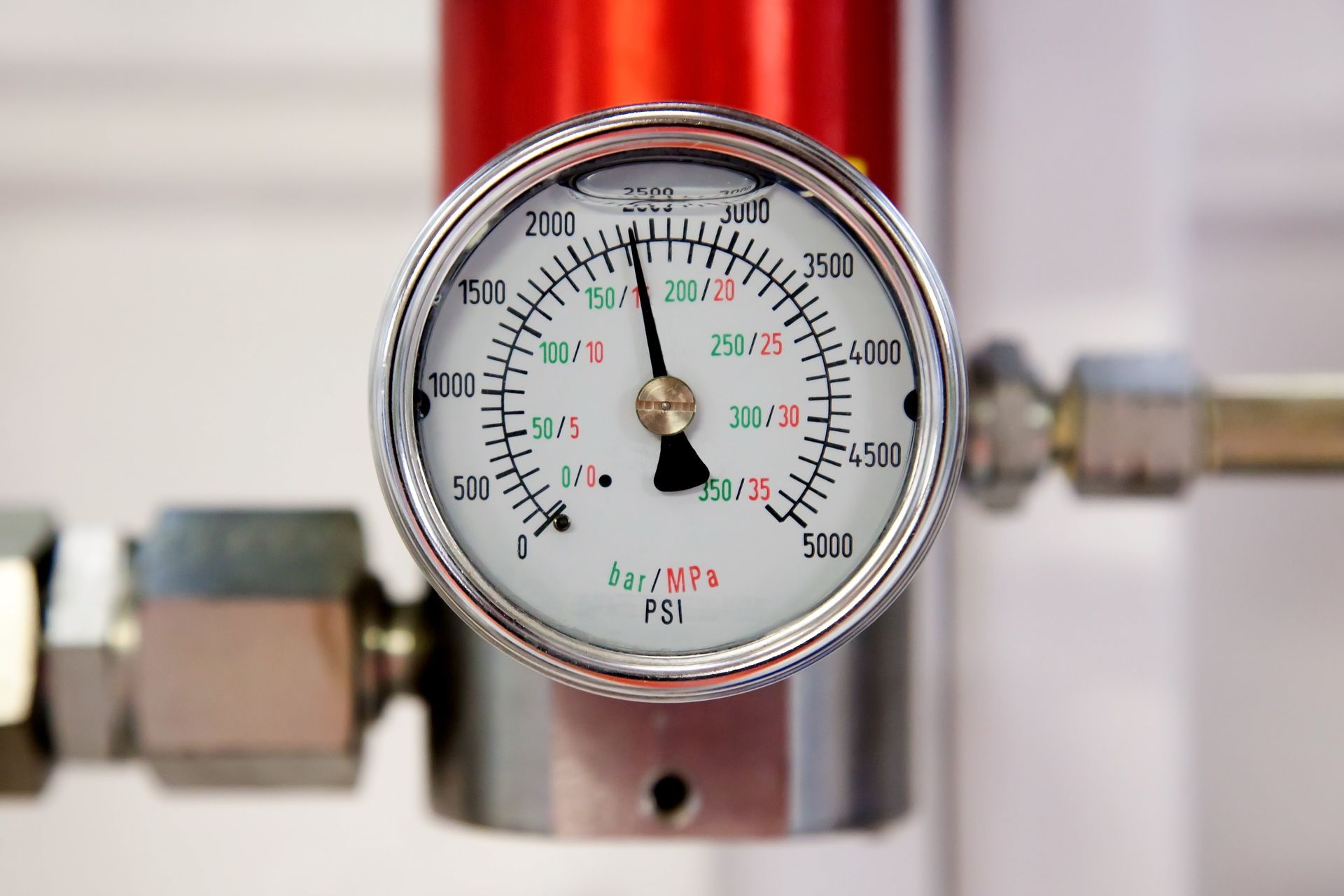

6. Inflation and Curing: The liner is inflated and pressured against the damaged pipe's interior walls. The resin cures, subsequently hardening and forming a new pipe within the old one.

7. Final Inspection: A post-relining CCTV inspection is conducted to ensure the quality and integrity of the relining work.

2. Pipe Relining vs. Traditional Pipe Repair Methods: Comparing the Benefits

Pipe relining boasts numerous advantages over traditional pipe repair and replacement techniques, making it an increasingly popular choice among property owners and plumbing professionals.

Less Invasive

Pipe relining does not require large-scale excavation or disruption to the surrounding landscape, reducing the impact on the property and its occupants.

Time and Cost-Efficient

The minimally invasive process of pipe relining often results in quicker completion times and reduced labour requirements, translating to lower overall costs when compared to traditional pipe repair methods.

Durability and Longevity

The materials used in modern pipe relining, such as epoxy resins, boast a long lifespan and remarkable durability, ensuring that the new pipe will remain functional for years to come.

Versatile Application

Pipe relining is suitable for various pipe materials, diameters, and configurations, proving to be a highly versatile and adaptable solution for a wide range of pipe repair scenarios.

3. When to Consider Pipe Relining: Identifying the Right Scenarios

Pipe relining is an excellent solution for various plumbing issues, such as cracked or damaged pipes, tree root intrusion, and corrosion-related problems.

Addressing Damage and Blockages

For property owners experiencing persistent blockages, reduced water flow, or cracked pipes, pipe relining can be an efficient and effective solution to restore the plumbing system's integrity and functionality.

Proactive Maintenance

In older properties with a deteriorating pipe system, opting for pipe relining can be a proactive measure to avoid expensive and invasive repairs resulting from catastrophic pipe failure in the future.

Environmental Considerations

For properties with extensive landscaping or those situated in environmentally-sensitive areas, pipe relining's minimal disruption makes it an ideal choice for mitigating the potential damage associated with traditional pipe repair methods.

4. Trusting the Pipe Relining Experts at DCG Plumbing

Entrusting your pipe relining project to the experienced professionals at DCG Plumbing guarantees quality workmanship and exceptional results.

Technological Expertise

DCG Plumbing's use of the latest pipe relining technology ensures that your property's plumbing system will receive the most advanced and sophisticated solution available.

Extensive Experience

The skilled technicians at DCG Plumbing possess vast experience in handling pipe relining projects, ensuring that your property benefits from their wealth of knowledge, expertise, and commitment to customer satisfaction.

Conclusion

The innovative process of pipe relining allows property owners to address their plumbing system's challenges with minimal disruption, maximising efficiency, durability, and long-term functionality. By understanding the benefits and versatility of pipe relining, and entrusting your property's plumbing concerns to the seasoned experts at DCG Plumbing, you can be confident in making informed decisions that protect your investment and ensure a seamlessly functioning plumbing system for years to come.

Embrace the cutting-edge technology and unparalleled expertise offered by DCG Plumbing for your pipe relining projects, and experience firsthand how our commitment to quality workmanship and customer satisfaction can transform your property's plumbing system, saving you time, money, and stress as you navigate the complex world of pipe repair and replacement.